Laying the brick

Before proceeding with the laying of the brick, check that the support surface is perfectly clean and level, so as to allow the correct start of the factory. Possible irregularities in the support plane can be repaired by fixing it with mortar.

The sight wire is positioned coinciding with the upper edge of the course to be executed, serving as a reference to guarantee its horizontality.

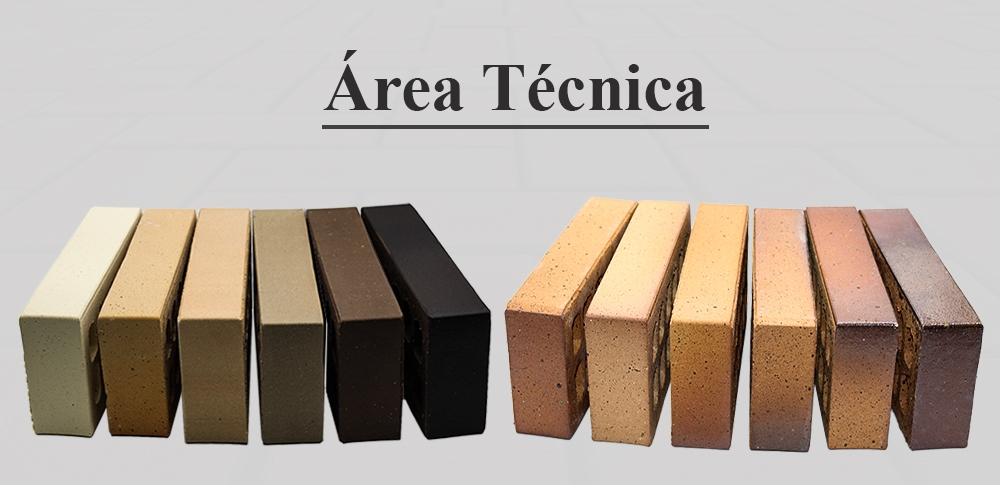

In order to achieve maximum homogeneity in dimensions and color, it is recommended to use brick two or three packages at a time, taken in staggered batches.

The bricks are laid always rubbing. To do this, it extends over the plane of seat, or the last course, a cake of mortar in sufficient quantity so that the line and the sore result from the specific dimensions (about 4 or 5 cm), and is matched with the trowel.

The brick stands on the mortar at a horizontal distance from the adjacent brick spun, previously placed, approximately twice the thickness of the sore. I know squeezes the brick vertically and scrubs, bringing it closer to the brick contiguous already in place, until the mortar overflows from the wound and the line, removing with the trowel the excess mortar.

To do correctly laying it is essential to add a quantity of mortar enough to fill the lines and the sores according to the thickness specified in the project and stakeout: poor execution causes the penetration of rainwater towards the soffit of the wall. If any joint is insufficiently filled, it must be covered with more mortar and press with the paddle.

It is counterproductive to move or hitting the bricks after the scrubbing operation and the initial leveling and alignment movements. Once the interaction between materials, blows and movements break the bonds chemicals and the parts no longer adhere well to the mortar. If it were necessary to correct the position of a brick, it must be removed by removing also mortar.

In the process of laying bricks it is important to avoid back and forth movement in the direction perpendicular to the wall since, if the layer of mortar when it has not yet hardened, the capacity is significantly reduced bearing of the factory, especially in the presence of eccentric loads. East The effect is noticeable on very slender walls.

Once the first yarn, the thread is lifted to the next mark, leveled and it proceeds to the placement of the second course, and so on.

The time interval between The operation of applying the mortar and placing the pieces is a factor that it conditions the adherence of the course that is placed with respect to the lower one. The water from the mortar arranged on the line is absorbed by the course on which settles and flow to upper parts is reduced the longer pass. It is most advisable to reduce the laying intervals of the pieces to a minimum.

Factories must be raised by horizontal courses in the entire length of the work, whenever possible. When two parts of the factory have to be built at different times, we must leave staggered in the one that is executed first, so that the one that is carried out later mount on the step. When this is not possible, arrange incoming and outgoing.

The traditional cleaner for the brick facades is hydrochloric acid. Most of the cleaners contain this acid in their composition. Its main function is to dissolve the cement from the mortar mix. It has few alternative uses and in many situations with presence of stains of another type NO MUST BE USED only use where there are remains of mortar and avoid touching the sore.

Maximum concentrations recommended:

In the case of bricks light colors the recommendation is 1 part acid to 20 parts water. In In the case of whites, it is advisable to use a neutral base.

For the rest of the bricks Clay is 1 part acid to 10 parts water.

Security Requirements

All acids and cleaners specialized are dangerous. Users are required by law to:

Get a copy of the card Manufacturer’s Safety Data Sheet (MSDS) for all chemicals used in the performance of your work and to only use the product in accordance with the instructions in the product safety data sheet.

In particular, you are reminded that hydrochloric acid is classified as corrosive. All the steps indicated for its use of the Product Safety Data Sheet.

To avoid personal injury We give users some recommendations:

Use all the necessary safety equipment that is detailed in the Safety Data Sheet, including, goggles or face mask, gloves and clothing protection as advised.

Pour acids into the water, and not vice versa. This avoids highly concentrated acid splashes on the operator.

If a cleanser is splashed with acid on the skin, it should be clean immediately with clean water and / or for greater efficiency with a solution of baking soda and water that will neutralize the acid. It should be sought medical attention regarding any injury caused by the use of products chemicals.

Chemical spills and spills must be treated in accordance with the recommendation contained in the Safety Data Sheet.